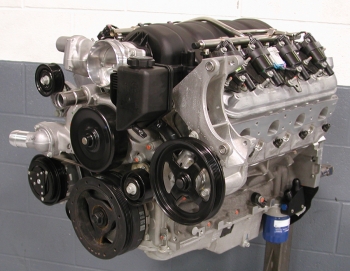

LS7 427 CID 650 HP 11.5 CRATE ENGINE with LS7 HEADS.

Lingenfelter Performance Engineering was founded over 42 years ago and is a globally recognized brand in the performance engineering industry. The company offers engine building, engine and chassis tuning components and installation for vehicle owners; component product development; services to manufacturers, aftermarket and original equipment suppliers; prototype and preparation of product development vehicles; late product life-cycle performance improvements; durability testing; and show and media event vehicles.

Lingenfelter LS7 427 CID 650 HP

11.5:1 compression ratio 93 octane fuel

• GM LS7 7 L aluminum block

• JE forged aluminum pistons high tensile 2618 T6 alloy

• Total Seal Premium file fit rings

• Callies 4340 forged steel Dragon Slayer crankshaft -58x reluctor

• Oliver 4340 billet steel 6.125 I beam connecting rods

• Clevite heavy duty HN rod bearings

• Federal-Mogul Speed-Pro heavy duty main bearings

• Lingenfelter LS 3 bolt cam conversion kit (L200175307)

• GM crank gear & HD timing chain

• Lingenfelter GT21 hydraulic roller camshaft (L210146006)

• GM LS7 dry sump oil pump

• GM keyed harmonic balancer

• GM LS7 lifters, lifter guides

• Corvette LS7 dry sump aluminum oil pan

• C6 Corvette valley cover, valve covers

• C6 Corvette rear cover

• Multi-layer steel (MLS) cylinder head gaskets

• GM head bolts, crank bolt

• Lingenfelter CNC ported & polished LS7 cylinder heads

• LPE Ferrea double valve spring kit (L230036006)

• GM LS7 2.205 diameter titanium intake valves

• GM LS7 1.615 diameter hollow stemmed sodium filled exhaust valves

• Competition Cams HD pushrods

• GM LS7 roller rocker arms, rocker arm stands, bolts

• LS7 Corvette composite intake manifold – fuel rails

• 90 mm throttle body, electronic

• 50 lbs/hr at 58 psi (4 bar) fuel injectors

• LS7 coils

• Magnacor spark plug wires

• LPE logo Koolsox wire protectors

• LS9 iridium spark plugs

• Lingenfelter Precision Built Engine certificate of authenticity

Component Preparation:

• All internal parts de-burred, hand washed & inspected

• Pistons, pins and connecting rods are pin fit

• Crankshafts – computer balanced to .2 grams per inch

• Chamfered oil holes & bearing surfaces micro polished

• Cylinder Block align hone checked / machined

• Precision honed on a Rottler HP6 with torque plates

• Hand de-burred, bolt holes are checked and re-tapped

• Cylinder heads precision 3 angle valve job to maximize flow & provide extended life

• CC checking chamber size for correct compression, surfacing to insure deck flatness

• Deburring, pressure testing, professional assembly, setting spring height

• Checking all tolerances

• Professional assembly & blueprinting

Lingenfelter Precision built custom engine assemblies for street and race applications can be ordered with many additional components and features. You can select specific options to make your engine assembly exactly as you need it.