We design, engineer and produce the best suspension components in the industry… and we are always innovating, always improving so we can keep making that claim. The key to being the best isn’t always as obvious as it might seem. Some might think that being the lightest, strongest, fastest, most durable, or even the best looking are the targets for being the best. Of course those are important features of our products, but what is the absolute, most critical, component of our entire approach to being the best? Problem solving!

We solve your problems.

We know that ultimately we are in the business of service – we exist to serve our customers and solve their problems. Every design parameter, engineering spec, manufacturing tolerance, and in fact all our business decisions are focused on that one goal – to solve your problems.

Ask around, talk to people about their experience with air suspension… it won’t take too many conversations until you hear a horror story of bad ride quality, busted air bags, leaking air lines, blown fuses, dead batteries and general frustration that would make the most confident of mechanics think twice about using air suspension.

Fortunately, we have been in the business of solving those problems for over 20 years. We have thousands of enthusiastic air suspension customers who can give you a very different story. We know that a properly designed air suspension system, with quality components and thoughtful installation can be one of the best ways to get your ride just the way you want it.

(Note: most horror stories start with “I knew a person who installed air bags once…” don’t take second hand accounts of days gone by and unknown installation practices… we can connect you with real customers who can tell you just how happy they have been with their Ridetech air suspension systems)

We know (from literally thousands of success stories) that air ride suspension can provide:

- Superior Ride Quality

- Great Handling

- Unmatched Adjustability (for load capacity – or just for the fun of it)

- Years of trouble free service

Number 5:

Leaks

To keep an air ride suspension leak free you need to focus on two things…

High Quality Components:

Many folks try to save a few bucks by using air solenoid valves designed for industrial use (think in a shop where a constant, endless supply of air fueled by giant compressors) where a small amount leakage is expected and not a big deal… many of the available valves on the market are actually designed with leak percentage built in… Ridetech valves are designed for use in suspension systems on vehicles. The acceptable leak rate is ZERO.

Same goes for air line fittings and connectors. Using DOT approved premium quality lines and connectors nearly eliminates the possibility of leaks from the components themselves.

Proper Installation Techniques:

If you use the best components (like the ones we sell on our website) and still experience leaks, then really the only other source is from improper installation. From years of experience we find that rubbing or clearance issues are the biggest cause for leaks in an air system. Routing airlines where they don’t rub, get pulled or otherwise interfered with is critical to having a long, leak free, life from your air suspension. Beyond that, the simple technique of using an air line cutter that leaves a perfectly smooth and tight seal and properly use of thread sealant on fittings will dramatically decrease the potential for leaks.

-

Tubing Cutters$13.00

Tubing Cutters$13.00

Detailed install instructions are included with our RidePRO E5 system – and you can download them online as well.

Number 4

Issues with wiring

In the most simple of applications, you can skip an onboard air suspension control system and manually inflate / deflate the air bags using Schrader valves (like your tires). This can be a good option for load leveling, but leaves out so much of the advantages of air suspension.

To truly get the “coolness” from an air ride suspension system, you need to provide an air supply in the form of an onboard compressor, air tank, and controls to inflate and deflate the air springs when the need (or desire) arrises – a system like the RidePRO E5.

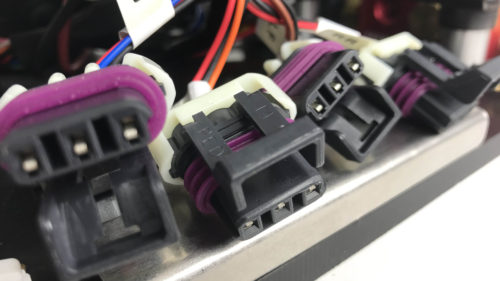

This means wiring a compressor control system into the vehicle. As with any additional wiring, every splice, each plug, is a possible addition of a problem. That is why we supply the highest quality wiring harness available, using premium wire, and high quality weather sealed connectors.

Even with the best of components, it is critical to supply the system with proper voltage. The single most common air suspension control system issue we deal with is poor voltage to the ECU or compressors. Typically this is caused by either poor grounds or a low battery.

It is super common for folks installing a new air suspension to get anxious to see the car or truck inflate and deflate. On a running driving car, where the charging system is good and the battery is fully operational, this usually turns out fine. On the other hand, when the car is a “project” and partially completed, the temptation is to toss any old battery laying around the shop and run the air suspension system.

Always make sure your air suspension control system is receiving full voltage – well over 12 volts with a properly charged battery and fully operating charging system – with the car running.

Number 3

Rough Ride

Suspension systems exist to absorb and smooth out bumps, ruts, ridges, dips and all other forms of road imperfections. A properly designed and installed air spring is fully capable of providing at least as good, and in most cases vastly superior ride quality when compared to steel coil-springs or leaf springs.

However, to accomplish its task, the suspension must move… and the amount of suspension movement, or “travel” needed is typically more than many people think. Proper suspension design is critical to allow for enough travel to smooth out the ride.

However, providing enough travel is not generally the main cause of poor ride quality from air ride equipped vehicle. The usual culprit is improper inflation of the air springs. Both over inflated or under inflated air bags will result in significant ride quality issues.

Of course, we all want to get our vehicle as low as possible, but if you want good ride quality you need to properly inflate the air spring to its designed ride height – and yes, each and every air spring has a built in height it works best at and a load capacity it was design for. That is why Ridetech uses a wide range of air springs to match each application with the correct load capability and stroke length.

Using our RidePRO E5 system allows you to set your ride height once and know that every time you drive, your suspension travel is optimized and your air springs are inflated to the appropriate level.

Number 2

Poor Handling

There are a bunch or reasons a car or truck may handle poorly. The most important thing to understand is the use of an air spring to support the weight of the vehicle has absolutely no inherent issues with handling. To the vehicle, a spring is a spring…

But we have seen a bunch of vehicles put on air incorrectly that were down right scary if the road wasn’t perfectly straight… so what went wrong? To start with, the same issues that effect ride quality can also dramatically effect handling. Lack of travel, improper inflation and use of the incorrect air spring in the application.

There are also a some folks that try to overly simplify the install and use a single air line and T-connector for more than one air spring. It is possible to inflate and deflate your car or truck two springs at a time, but if two air springs share an air line, when the vehicle enters a corner, the air springs will actually transfer air pressure from one spring to the other – this is bad… VERY bad. It causes erratic and down right dangerous handling characteristics. This was a mistake made more often back in the early days of air ride suspension (by mostly inexperienced builders). Unfortunately those “wonky” handling cars and trucks still haunt the reputation of modern air suspension.

All our Ridetech control systems are designed to control each spring separately. It is really the only way to do it right.

Also key to handling, and ride quality is use of a proper shock. In many cases an air suspension vehicle is operating at a lower height and requires a shock designed to work at this lower height. Ridetech uses premium Fox Shocks to provide the ultimate in dampening for air suspension cars and trucks.

We are confident in our ability to provide complete suspension systems that excel in providing both superb ride quality as well as pavement ripping handling.

Number 1

Frustration with inconsistency

We love air suspension systems and we know how much fun it can be to have complete control over the hight of your car or truck at your fingertips. At first, you want to push the buttons all the time… continually experimenting with it… in fact, playing with it. We get it… it is fun.

However, for many folks, there comes a time where you just want to drive your car and not have to fidget with getting your air springs to the perfect air pressure… you just want to drive. Many air suspension control systems are simply valves and switches that you have to be the brains for… which means you are going to be required to manually adjust for changes in load, even changes in temperatures – constantly adjusting to get your suspension just right.

With our RidePRO E5 system you can choose to not have to think about your air suspension at all. The advanced computer control system automatically calibrates to your specific vehicle and learns how to best achieve the exact ride height every time you start the engine.

The system is so smart, you won’t have to think about it at all… until you want to show off again.

So the top 5 problems with air suspension aren’t problems at all for us. in fact we don’t have ANY problems with air suspension. We have solutions!

Is there any thought to a front up/front down Rear up/rear down buttons? Instead of holding two buttons at a time. A lot of times if your pulling in somewhere you just want to bump the front up or rear. Holding two buttons is cumbersome.

The ridepro system includes 3 programmable presets, these can be set up to do the same thing. I use 1 for dropped height, 2 for ride height, and 3 for front up to clear the driveway.

Have no power to compressor or control module all of a sudden?? Need help.. thanks.

The compressor power wire should go direct to the battery. Check the wire to make sure nothing as cut it, shorting out, fuse is blown, etc… The ECU should also have a power wire going direct to the battery, do the same for it. You should also check your ground wires to make sure they’re still tight (and have a good, solid ground). It sounds like you have something that has either come disconnected or cut.

I just inherited a ’51 Chevy Rat Rod. It has a system from you guys. The remote is a LevelPRO with 3 settings. Are these a preset height? I have no information on how to use it correctly. I didn’t know if there was a manual that I could get.

Hey Joe,

We can send you the instructions, no worries. Just call into our main line and one of the guys can email it to you.

How do I stop the system from bottom all the way down do you have spacers for the air bags so it doesn’t touch the pavement and I can’t install stop bumps on the front I have a mustang 2 suspension please help thanks

We always recommend installing bump stops.

Does this controller work with other systems? I purchased a 1950 Chevy truck with an airmaxx system and need to fix it. It’s bouncy or bottoms out.

Our Ridepro system will run other compressors and utilize other brands air tanks. If you are having trouble with “bouncy” suspension, it probably isn’t the control system. It is most likely shocks or a lack of suspension travel (either topped or bottomed out). Give us a call and we can work it out with you.

I have a problem with the front air bags…..when bags are inflated and deflated it rubs the sway bar link and it blows the front bags out…….what can I do?????

What application are you working on. Any rubbing of an air spring is going to result in trouble.

My name is Randy my question is I have a simple air ride airbag system on my F250 to help carry my camper. After sitting unloaded for a year or two the airbags will inflate and deflate slowly up to about 20 pounds. But if my airbags are inflated to a higher poundage such as 80 pounds they will not deflate. The only way they would Deflate is if I manually deflated them. Thanks for the help

if this system uses a solenoid valve, you might want to clean them out. here is a guide to assist… https://ridetech.com/tech/solenoid-valve-service/

What’s would be the cause of a system installed and stereo system works fine but when hitting the switch’s u hear popping from the speakers when pushing switch up or down

How do I get rid of it I’ve tryed everything from doin some titanic iron man grounds frm every where possible and to no avail . Plz help it’s 10/985 cutlass supreme 350 swap

It almost has to be a ground or possibly a positive lead… try running the grounds directly to the battery.

I need help with check valves always leaking back thru compressor or failing? Am i doing somethings wrong?

what compressors do you have? most have a check valve built-in, some have it in the braided line.

Sometimes when my car sits for a while the back will raise up on it’s own but sometimes it leaks. What could cause that

sounds like a sticking valve, here is a great guide to help you out. Thanks https://ridetech.com/tech/solenoid-valve-service/

Why do my front air struts leak air when I drive them at a low psi, they tend to drop as if I make turns. Sometimes it makes my compressor fill up the tank with 100 psi to have them aired up properly.

if the pressure in the tank is below bag pressure the system will back feed through the valves. your tank should have 150psi in the system at all times.

My air bags hold air just fine until I start driving, when I was on the highway they all dropped, I’ll put it into off-road 1 let it sit hold or have it in normal mode and they hold, it’s when I’m driving they will lower

is this an OEM application? or a Ridetech Air suspension system?

Hey I have a ridepro setup on my 56, brand new manifold two tanks two compressors with an old school are ride tech controller, I’ve been having issues where the front bags fill up on their own no leaks anywhere and that’s without battery power, any ideas?

Hi I have finally got my car, a 1955 Buick Special with Corvette C4 suspension, out on the road, and have some issues on the handling. It is very bumpy and it seems like the shock absorbers dosen´t do what they should. Can it be that there is too much pressure in the bags? Have tried to adjust the shocks with no significant changes.I have HQ 1000 shockwaves in all 4 corners and Airpod with 2 compressors

make sure the vehicle is at the proper ride height, adding too much or not enough air will cause the ride to suffer. try airing the car all the way up, measure the fenders to the ground and drop it 2″-3″ this should give you the proper travel. start with the shocks in the middle of adjustment 12 clicks. these 2 things should help the ride quality.

I have a 350z with an ALP 3H system, recently the passenger rear air bag has not taken in any air at all, it’ll stay at 0 while all the other bags take in air just fine, is this a leak issue or an issue with the manifold?

Well, we dont sell or tech Air lift products, but check the power to the valve; that will tell you if it’s in the valve issue or not.

Hello , I’m having issues with my airtekk stage 2 system , my compressors are not coming on also it started with my remote not being able to lift the car it will only air out , checked the pressure switch and it was bad so I changed it , so you think the relay could be bad too ?

A power tester will help you trace the power. check fuses also, could be a bad fuse.

Hello 🙂 my caddie has a ridepro e3. It’s been sitting in the garage for a month. When I tried to start the car the battery was almost dead. I gave it aim start help. It fired up. But the compressor runs all the time. Even when ignition is off. It’s never done that before. Do you have some advice? All fuses ok. Ground and power is as it should be.

Give us a call. We can go over the system and help you out. Thanks

I had a dealership (Suburban Harley in WI) put on the dirty air system. I have a 2016 street glide special. I had the front and back with center stand done. Now when I ride there is noise and feeling similar to the triple trees being loose. I feel and hear it with every bump in the road. I have taken it back to the dealership and had another person check out the neck/triple trees and they both said theres nothing wrong. someone suggested that there may be a problem in the front shocks. Is this a problem that the company has come across. If so what are some solutions I could explore.

We dont make any motorcycle suspensions?

Hi,

I installed Ride Pro System on my Monte Carlo SS in July of 2014. Although only a couple thousand miles in that time the system has been trouble free up until recently. At start up the compressor will come on at 134 psi and pump very slowly finally reaching up to about 142 psi and not shut off. If I shut the car off and start up again the compressor will be off then and start up again when psi drops to at about 134. This is a single compressor system. Do I need a new compressor?

Hey Clare,

It sounds like the pressure switch and compressor are doing their job properly. I believe you have a leak between the tank and compressor or between the tank and the valve, not allowing the compressor to fill the tank up completely and shut off. I would recommend spraying the connections with some soapy water and watching for bubbles. Another thing to do is drain the tank pressure completely and pull the airlines out. Over time, they’ll move around and a groove will wear in them and create a leak point. All that would need to be done in that case is to make a clean cut behind the groove and plug it back in.

-Josh